PE Foam Tube Extrusion Line

Overview

Manufacture qualified expanded cellular Polyethylene Foam Tube & Rod™ using Butane gase foaming method; each stage precisely controlled automatically

Features

- Polyethylene based product inert material

- Highly resistant to chemicals

- Environment friendly product: free of CFC, HCFC and chemical blowing agents

- 100% recyclable

- Flexible low weight material, easy to slip and install

- Low thermal conductivity

- Compatible with all sealing materials

- Fine round closed-cell cellular structure assures : negligent absorption and water permeability

- Excellent impact and compression resistance even for low thicknesses

Application

- Plumbing

- Heating and Thermal Conduction,

- Refrigeration

- Air conditioning insulation

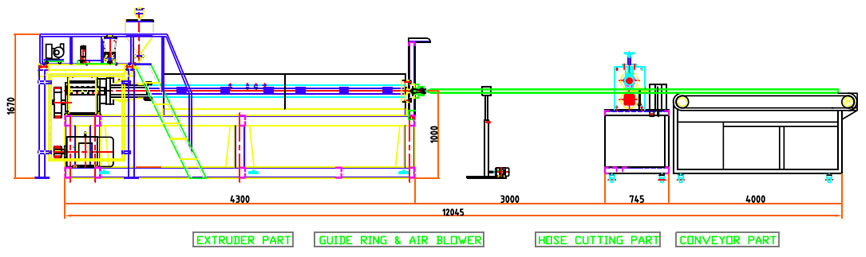

Layout

Specifications

100-80

Layer

2 layer, 3 layer, 5 layer

Width (mm)

1000-1600t

Thickness (mm)

0.02-0.08

Bubble Size

Ø10x4mm Ø20x5mm

Capacity (kg/hr)

250

Speed (m/min)

5-35

110-90

Layer

2 layer, 3 layer, 5 layer

Width (mm)

1000-2000

Thickness (mm)

0.02-0.08

Bubble Size

Ø10x4mm Ø20x5mm

Capacity (kg/hr)

320

Speed (m/min)

5-35

130-100

Layer

2 layer, 3 layer, 5 layer

Width (mm)

1000-3000

Thickness (mm)

0.04-0.08

Bubble Size

Ø10x4mm Ø20x5mm

Capacity (kg/hr)

450

Speed (m/min)

5-35

Contact

Our friendly operators are standing by to serve you. Give us a call now!

Location

905-7, Wolam-dong, Dalseo-gu(Industrial Complex), Daegu, Republic of Korea

Industries

Vacuum Forming

Foam Production

Foam Sheet Production

Foam Recycling

Foam Bag Sealing

Foam Net Extrusion

Foam Tube Extrusion

Foam Pipe Forming

Foam Sheet Cutting

Foam Sheet Extrusion

Foam Sheet Bonding

Foam Sheet Lamination

XPS Foam Board

Air Bubble Film Extrusion

Copyright © foamtech-korea.com 2020. All Rights Reserved.